One apparent disadvantage of twist lock connectors is that in the event that the cable is accidentally pulled too hard rather than the plug falling out of the receptacle.

Twist lock connector definition.

The tensile strength of a twistlock is rated at either 20 or 25 tonnes.

To unplug the plug must be twisted the opposite direction.

Cs6361c cs6377 cs6360c cs6370 custom.

They turn to lock together when mated to prevent accidental disconnection.

A twist lock receptacle is an outlet that requires a plug to be twisted into it in order for it to be connected and stay in place.

One apparent disadvantage of twist lock connectors is that in the event that the cable is accidentally pulled too hard rather than the plug falling out of the receptacle exposed conductors may come out of the plug causing dangerous shorts or shock hazards if the circuit is live.

Benefits of a twist lock receptacle.

Get free shipping on qualified twist lock electrical plugs connectors or buy online pick up in store today in the electrical department.

A twist lock is beneficial in those environments.

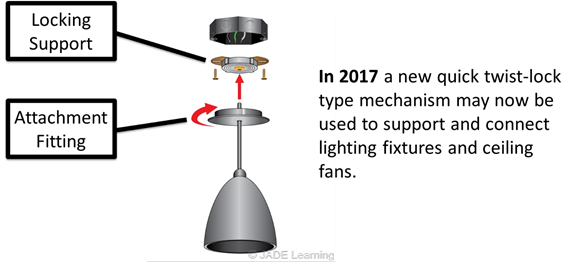

A power plug and receptacle in which the plug must be twisted after insertion to lock it in place to guard against the plug accidentally being knocked loose explanation of twist lock connector.

Looking for twist lock connector.

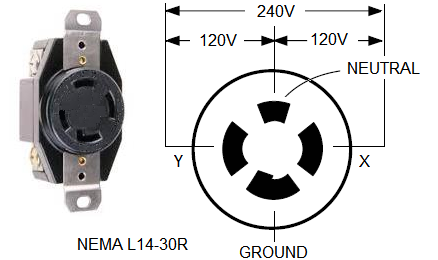

Nema twist lock blades.

Unlike a regular wall receptacle that requires you to push the plug into the socket holes to make a connection twist lock receptacles utilize a twisting method with a plug to.

Also known as twist lock devices these connectors withstand tough repetitive use and are more durable than standard turn lock connectors.

Without this process the electrical device cannot be disconnected from the wall.

What is a twist lock receptacle.

Configuration male female voltage amperage wires poles standard cord plug inlet connector outlet receptacle adapter.

The mechanism is similar to that of a kensington lock but on a much larger scale.

The male connector usually has curved prongs that plug into the receptacle and then are twisted to lock into place.

The maximum size and position of the holes in the connector is defined in international standard iso 1161 1984.

This is resolved in most cases by the connector having a robust.

The locking coupling makes for a more reliable connection in commercial and industrial settings where vibration or incidental impact could disconnect a non locking connector.