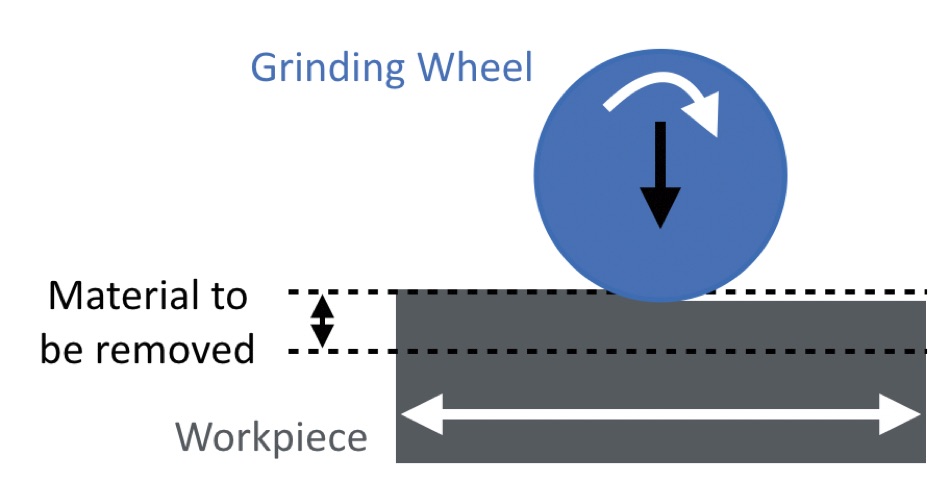

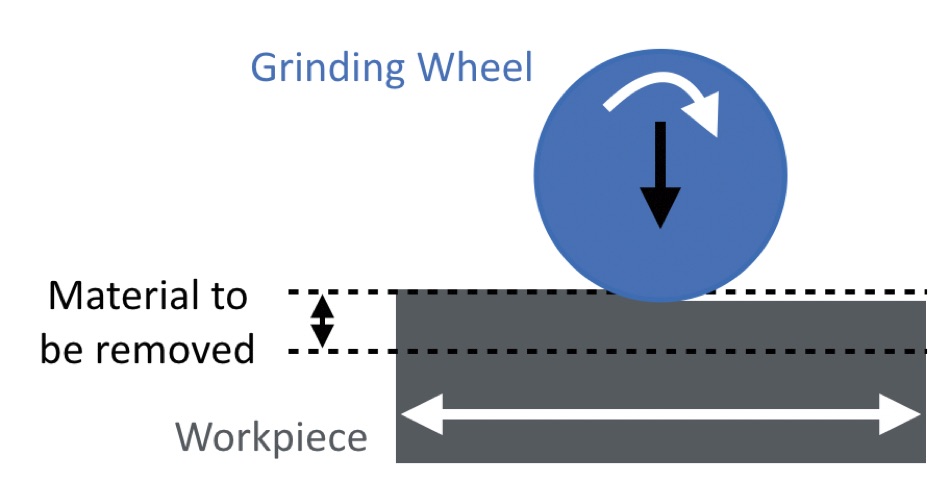

It is used to make a flat surface the rotating grinding wheel removes the material from the top surface of the workpiece gives a flat look.

Types of grinding machine ppt.

These are different types of.

Types of grinding wheels.

However tools and cutters with complex geometry like milling cutter drills reamers and hobs require sophisticated grinding machine commonly known as universal tool and.

This machine is almost similar with the cylindrical grinding machine but it has very precised lead screw for producing the accurate pitch on the threaded part.

The surfaces may be straight tapered steps or profiled.

There are many types of tool and cutter grinding machine to meet these requirements.

The tool is hand held and moved across the face of the wheel continually to avoid excessive grinding in one spot.

Types of surface grinding machines tool and cutter grinder in grinding tools by hand a bench or pedastal type of grinder is used.

External grinding machine work piece type.

Broadly there are three different types of cylindrical grinding machine as follows.

Each grain of abrasive on the wheel s surface cuts a small chip from the work piece via shear deformation.

Simple single point tools are occasionally sharpened by hand on bench or pedestal grinder.

Cylindrical grinding machine this machine is used to produce external cylindrical surface.

For sharpening miscellananeus cutters a universal type grinder is used.

This type of grinding operation is performed only for cylindrical jobs.

Cylindrical surfaces may be straight curved or contoured.

This is a type of special grinding machine having a special grinding wheel.